Ginger Dosier

I Grow at the Water’s Edge

Certainty is the root of despair. The inevitable stales, while doubt and hope are sisters. Not unfortunately the universe is wild—game flavored as a hawk's wing. Nature is miracle all.

B.P. Blood, as quoted by William James, “A Pluralistic Mystic”, Hibbert Journal, 1910

I was eight years old when I first saw the ocean. It was July 1986 and before the sun came up, my parents packed my older sister, brother, and me into our Pontiac station wagon to take the eight hour drive from Huntsville to Gulf Shores. As we drove the length of Alabama, I peered out the window for signs of the beach and the ocean horizon. In the trunk, cramped between luggage, towels, and a plastic cooler, my vinyl bag sat crumpled, waiting to be filled with seashells. My parents had started their collection of shells while honeymooning in Panama City; I was eager to start my own.

The pines that lined the highway opened at Bay Minette, then vanished as we approached the Mouth of Mobile Bay. We had reached the beach. And as we dragged our gear along the path between the dunes, I paused a few hundred yards from the water. In front of me, a pale yellow spiral poked from the sand. A whelk. I leaned down to inspect its twisting spines, and a question rose in me: How was this intricate thing possibly made?

I can’t claim that a single seashell set the course of my career. More often, we assign meaning to moments in hindsight. But that twisting perfect structure led me to architecture and how it’s made. I have studied building materials for 30 years, and while architects choose their materials over the course of a few hours or months, the structures themselves wear those choices until their dying day. Material decisions become a building’s life sentence.

I returned again and again to that whelk, asking myself how I might grow something so intricate, or more literally and perhaps even radically, grow a material in the way a whelk grows its shell.

One of the most surprising aspects of shell-making is that it requires the cooperation of, not one or two, but dozens if not hundreds of species. While the mollusk lays calcium layer by layer, a consortium of microbes change the chemistry of the water to allow for the shell to crystalize. The more I read and observed, the more I came to see the signature of microbes everywhere.

Two decades later, now an architecture professor in North Carolina, I again found myself racing to the water’s edge for inspiration—this time on the Outerbanks. It was Labor Day weekend. The air was chill, the clouds heavy, threatening to storm, and the waves, violent. After changing into a swimsuit, I waded in. Sharp grains of sand scraped my legs as the waves recoiled. I lingered in the water until dark, gathering sand and shells in buckets, petri dishes, and jars to bring home. For all the discomfort, I felt like I belonged.

With no biology lab in the architecture department, I had converted our second bedroom into a lab, filling it with second-hand equipment. Under the microscope, coccoliths and diatoms looked like glass seeds and burs, some smoothly spherical, others prickly with spines. I could see how microbes glue layers of sand to create beach rocks, which they then use as homes to protect themselves.

The architect, Louis Khan famously said that when you ask a brick what it wants to be, it replies, “an arch.” When I asked our microbes the same question, it sounded more like an onrush of answers.

At magnification, the way these organisms collaborate to create strength offered a blueprint for how to build our own terrestrial structures. What if we made architecture the way marine life makes its forms and structures? Bricks being the smallest unit in building, why not start there, why not grow bricks in the way marine bacteria help build shells or bond together beach rocks?

Over the next five years, I grew thousands of bricks using bacteria, each brick one-twentieth the size of a normal brick, each nurtured with a different formula, temperature, and pH. Like with plants, they needed watering and feeding. Unlike with plants, my nose was my guide. Smells signaled contamination. Some contaminants smelled like fruit. Others were indescribably repulsive, something akin to rotten vegetables.

After the bricks grew to form, I submerged them in water for 24 hours. If they held together, they would move onto compression testing. And when I finally succeeded with tiny bricks, I moved to full-scale bricks.

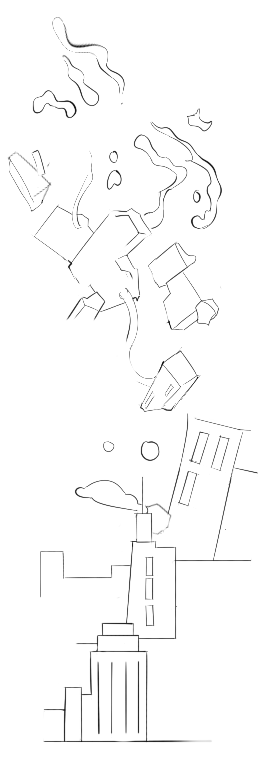

By this time, my home lab had become a business. What began as a solitary curious experiment in a spare bedroom evolved into a company spanning more than fifty disciplines—architects and biologists, chemists and engineers, financiers, lawyers, systems thinkers, commercial operators—each testing what it means to build and scale with life. Progress was measured through persistence: thousands of iterations, countless failures, and an almost cellular kind of grit.

During one production run, a brick paver crashed to the floor and cracked in half. We placed the pieces back into their tray. A day later the paver had fused back together. The joint left a light scar. I’d never seen a concrete block heal itself. Nature’s elegance was manifesting.

I spent two intimate decades with Sporosarcina Pastuerii, the bacteria we used for microbial cementation, from the first isolation plate to international commercialization. Portland cement was invented 200 years ago by Joseph Aspdin in his kitchen. It is the second most used substance after water, and it enabled our modern world. But I doubt Aspdin could foresee its negative impacts—cement is responsible for eight percent of the world’s carbon emissions. Easier, more efficient, more environmentally sound—under the right conditions, we could replace Portland cement with a microbial medium that eliminates the need for cement factories and the fleet of ships to transport it around the world.

The architect, Louis Khan famously said that when you ask a brick what it wants to be, it replies, “an arch.” When I asked our microbes the same question, it sounded more like an onrush of answers—”seawalls, runways, soil stabilizers, and yes, bricks, pre-cast concrete but also so much more.” Perhaps this is the property of being alive, endless opportunities.

Often, I find myself looking at the world around me with the eyes of my eight year old self. Microbes were the architects of this world long before we had words to name them. From shells and stromatolites, to stalactites in caves, all are made in part with microbes. They built the limestone cliffs, coral reefs, the first soils, and the oxygen we breathe. Microbes are infinite libraries of knowledge. And, I suppose they are training my imagination. They’re right here—everwhere—offering answers. My work now is to listen and to follow their collective lead.

Ginger Krieg Dosier is an award-winning architect, scientist, and entrepreneur best known as co-founder and former CEO of bioMASON, a biotechnology company that grows building materials using microorganisms. She is the founder and executive director of BIOME Consortia. Ginger was an assistant professor of architecture at the American University of Sharjah in the United Arab Emirates and North Carolina State University. She earned her Masters of Architecture from Cranbrook Academy of Art and undergraduate degree from Auburn University. Biomeconsortia.org